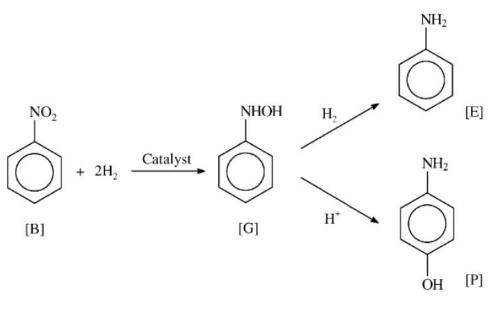

4-Aminophenol synthesis

- Product Name:4-Aminophenol

- CAS Number:123-30-8

- Molecular formula:C6H7NO

- Molecular Weight:109.13

synthesis of 4-aminophenol

36309-42-9

1 suppliers

inquiry

123-30-8

625 suppliers

$10.00/5g

Yield:123-30-8 98%

Reaction Conditions:

with methanol;1,3-disulfonic acid imidazolium hydrogen sulfate at 20; for 0.0666667 h;Green chemistry;

Steps:

General procedure for the deprotection of trimethylsilyl ethers

General procedure: A mixture of the substrate (1 mmol), ionic liquid [Dsim]HSO4 (6.5 mg, ~0.02 mmol) in methanol (2 mL) was stirred at room temperature. After completion of the reaction (monitored by TLC), solvent was evaporated, water (1 mL) was added to the mixture, and stirred vigorously. Decantation of the mixture gave almost pure product(s). The products were characterized by comparison of their IR and NMR data. The ionic liquid was dried at 65 ?C under vacuum to remove moisture, and then reused.

References:

Shirini, Farhad;Khaligh, Nader Ghaffari;Akbari-Dadamahaleh, Somayeh [Journal of Molecular Catalysis A: Chemical,2012,vol. 365,p. 15 - 23]

89415-43-0

155 suppliers

inquiry

123-30-8

625 suppliers

$10.00/5g

24541-43-3

5 suppliers

inquiry

123-30-8

625 suppliers

$10.00/5g

100-02-7

60 suppliers

$11.00/5G

123-30-8

625 suppliers

$10.00/5g