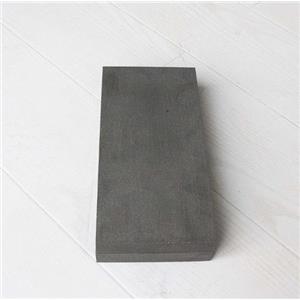

Best Quality Sic Plate Refractory Silicon Carbide Kiln Plate NEW

| Price | $13 | $9 |

| Package | 10piece | 30piece |

| Min. Order: | 100piece |

| Supply Ability: | 20T |

| Update Time: | 2024-05-23 |

Product Details

| Product Name: Best Quality Sic Plate Refractory Silicon Carbide Kiln Plate | Min. Order: 100piece |

| Purity: 99.5% | Supply Ability: 20T |

| Release date: 2024/05/23 |

Basic Info.

Product Description

Product Description Of Silicon carbide plate

Silicon carbide plate used the high purity silicon carbide(SIC) and industrial silicon powder as the primary materials.Shaped by vibration,made by high sintering.

Silicon carbide plate silicon carbide bricks, sheds, brackets and silicon carbide special-shaped parts produced with silicon carbide as the main raw material not only have the inherent characteristics of silicon carbide such as high strength and high hardness, but also have high refractoriness under load, fast heat conduction, anti-oxidation, It is not easy to shrink and deform under high temperature, and has the characteristics of long service life.

Silicon carbide plate product specifications

Silicon carbide plate used the high purity silicon carbide(SIC) and industrial silicon powder as the primary materials.Shaped by vibration,made by high sintering.

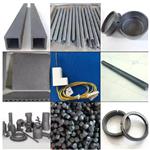

Silicon carbide plate features

1. Good thermal conductivity

2. Good high temperature strength

3. Wear resistant and erosion resistant

4. Good thermal shock resistance

5. Good corrosion resistance

6. Good oxidation resistance

Silicon carbide plate application

1. Non-ferrous metal smelting industry,ceramic,enamel and cement rotary kiln mouth, as well as glass annealing furnace and various kind of high temperature furnace.

2. Blast furnace lining,the lining of aluminium electrolytic bath,glass tank,structural ceramics,sanitary ceramics,domestic ceramics,electrotechnical porcelain refractory material, sinter powder metal industry.

3. Industrial ceramics bearing plate burning,pushing board, sagger; muff plate of annealing furnace;lining and ignitor of CFBB; lining of garbage incinerators,heat treatment electric heating furnace,soaking pit furnace etc.

If you want to know more products, please contact us immediately, we have professional engineers to answer your questions

![]()

If you have more needs, we can customize the size, material, etc.

Silicon carbide plate specification

Properites | Units | Silicon carbide Material | ||||||

Type | SiC | SiSiC | NSiC | RSiC | ||||

Chemical composition | SiC% | 89 | 87 | 92 | 70 | 99 | ||

SiO2 % | 5 | 6 | - | Si3N4 28 | - | |||

Al2O3% | 1.0 | 2.0 | - | - | - | |||

Bulk Desity | g/cm3 | 2.85 | 2.8 | 3.01 | 2.8 | 2.75 | ||

Apparent porosity | % | 12 | 14 | 0.1 | 12 | 14 | ||

M.O.R.@20ºC | MPa | 50 | 48 | 260 | 180 | 100 | ||

M.O.R.@1300ºC | MPa | 58 | 56 | 280 | 185 | 120 | ||

C.T.E.@20ºC-1000ºC | 10-6K-1 | 4.8 | 4.2 | 4.5 | 4.7 | 4.6 | ||

C.C.S | MPa | 100 | 90 | 900 | 500 | 300 | ||

Thermal shock resistance | ★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | ||

Max working temperature | ºC | 1450 | 1420 | 1300 | 1500 | 1650 | ||

application | Used in ceramic shuttle kiln, tunnel kiln and roller kiln,Kiln furniture. | |||||||

![]()

![]()

Company Profile Introduction

You may like

-

CAS:

$15.00 / 10piece

-

CAS:

$13.00 / 10piece

Recommended supplier

| Product name | Price | Suppliers | Update time | |

|---|---|---|---|---|

| $/ |

Anhui Ruihan Technology Co., Ltd

|

2023-08-21 |

- Since: 2023-04-24

- Address: Room 010, House 308, No. 350, Juhuashan Road, Huangdao District, Huangdao City, Shandong Province

China

China