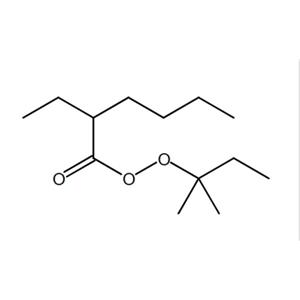

V8 Curing Agent NEW

| Price | Get Latest Price | ||

| Package | 20kg | 25kg | 30kg |

| Min. Order: | 500kg |

| Supply Ability: | 500tons |

| Update Time: | 2024-07-08 |

Product Details

| Product Name: V8 Curing Agent | Min. Order: 500kg |

| Purity: 99% | Supply Ability: 500tons |

| Release date: 2024/07/08 |

PHYSICAL PROPERTY:

Appearance: colorless to yellowish liquid

Density (20 ℃) : 1.070 g/cm3

Flash point:68 ℃

Refractive index (20 ℃) : 1.49

SADT: > 60 ℃

The active oxygen content: 8.9%

STORY:

Because organic peroxides are unstable during storage, they lose mass over time.There is a recommended storage temperature for each peroxide.According to the recommended storage conditions, the product specifications shall be maintained for at least 3 months after delivery.

The recommended storage temperature is <30℃

Safety in use:

Operate and use the product in a dry and well-ventilated environment, away from fire and heat, and away from direct sunlight.At the same time, avoid contact with reducers, acids, alkalis, dryers, promoters, etc.

Application:

V8 can be used as quartz curing agent.Typical dosage is 0.8-1.0% of resin dosage.

The common curing temperature is 80-100℃.

Curing characteristic:

Factors should be considered when selecting curing agent system:

1. The process

2. Resin type

3. Gel time and preservation period required

4. Product thickness

5. Room temperature

6. Nature of the additive

Curing performance comparison:

Curing condition: 80℃, the dosage of curing agent accounts for 1% of resin.

For OT, it is not easy to continue to increase the temperature to reduce styrene residue,the reason is that the exotherm temperature will be further increased and the curing speed will be accelerated, which will easily cause plate cracking.For V8, low exothermic peak can further increase the curing temperature to 85-90 degrees to reduce styrene residue.

Company Profile Introduction

You may like

Recommended supplier

| Product name | Price | Suppliers | Update time | |

|---|---|---|---|---|

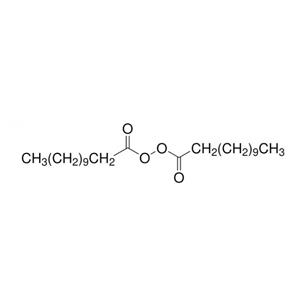

| $/ |

Anhui Ruihan Technology Co., Ltd

|

2023-08-21 |

China

China