Nylon 6/6 and nylon 6

Sep 21,2023

Description

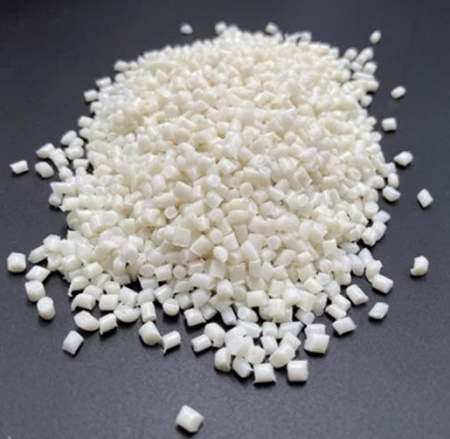

Nylon 66, also known as nylon 6-6, nylon 6/6, nylon 6,6, or nylon 6:6, is a type of polyamide or nylon. Nylon 66 is synthesized by polycondensation of adipic acid and hexamethylenediamine (HMDA). In 2016, the combined global market size of nylon 6 and nylon 66 was USD 24.44 billion, with an estimated compound annual growth rate (CAGR) of over 6.1% from 2017 to 2025[1].

Nylon 6/6 and nylon 6

Nylon 6/6 and nylon 6 are similar. They are both aliphatic polyamide-based nylons and are commonly used in the fiber and textile industries. However, their properties are different. Nylon 66 has higher resistance to heat and better mechanical properties than nylon 6, whereas nylon 6 has higher resistance to wear and is easier to process than nylon 6/6. Nylon 6/6 has a continuous service temperature of 210°F, slightly higher than Nylon 6 at 200°F. Nylon 66 is mainly used when high mechanical strength, rigidity, good stability under heat, and/or chemical resistance are required[2]. nylon 6, also known as polycaprolactam, is synthesized by ring-opening polymerization of ε-caprolactam. It is always used in the automotive, industrial, and military industries. Since its lustrous finish and is easier to dye, it has a better aesthetic appearance than Nylon 66.

Nylon 66 copolymers

The incorporation of nylon 66 into other materials had a significant effect. Such as improve the uniformity, tenacity, modulus, and amorphous orientation ability. The result revealed that with increasing nylon 66 concentration, the tensile strength of the copolymers increased, and the flexural strength and flexural modulus first increased and then decreased. However, its doping concentration needs to be investigated[3].

Reterences

[1] Lee Y, et al. Renewable routes to monomeric precursors of nylon 66 and nylon 6 from food waste. Journal of Cleaner Production, 2019; 227: 624-633.

[2] Prevorsek D, et al. Interpretive nonlinear viscoelasticity: Dynamic properties of nylon 6, nylon 66, and nylon 12 fibers. J. Appl. Polym. Sci., 1980; 25: 2063-2104.

[3] Jia F, et al. EMechanical and thermal properties of dimer acid based nylon 636/Nylon 66 copolymers. J. Appl. Polym. Sci., 2013; 131.

- Related articles

- Related Qustion

- Nylon 6/6: Characteristics, Applications and Advantage in Practical Applications Feb 23, 2024

Nylon 6/6 excels with enhanced properties over Nylon 6, offering toughness, wear resistance, and durability for industrial applications, emphasizing sustainability and environmental benefits.

Magnesium carbonate not only has a wide range of industrial applications, but also is commonly used in the treatment of bile reflux disease and gastric ulcer.....

Sep 21,2023DrugsLauroyl peroxide is widely used in industrial and experimental research....

Sep 21,2023Organic reagents