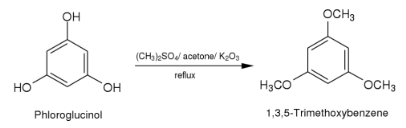

1,3,5-Trimethoxybenzene synthesis

- Product Name:1,3,5-Trimethoxybenzene

- CAS Number:621-23-8

- Molecular formula:C9H12O3

- Molecular Weight:168.19

Yield:621-23-8 99.5%

Reaction Conditions:

Stage #1: methanol;1,3,5-trisbromobenzene in toluene at 135; under 5320.36 Torr; for 0.75 h;

Stage #2: with triethylamine in toluene at 165; under 8360.56 Torr; for 11 h;Temperature;

Steps:

1-3

1) Mix methanol and catalyst, pass argon gas, control the pressure to 7 atmospheres, control the temperature to 135 °C, and maintain for 30 minutes.A solution consisting of 1,3,5-tribromobenzene and toluene was added dropwise, and the dropping time of the solution was controlled to be 45 min.After the solution was added, triethylamine was added dropwise, the dropping time of triethylamine was controlled to be 10 min, triethylamine was added, and the temperature was raised to 165 ° C.The pressure was raised to 11 atm and then the reaction was continued for 11 h.The preparation method of the catalyst is:The sodium oxide and the cerium oxide are mixed and ground, and after passing through a 700 mesh sieve, the sieved material is activated at 800 ° C, and the obtained mixture is mixed and ground with a dextran gel, and passed through a 500 mesh sieve;The weight ratio of sodium oxide to cerium oxide is 1:0.32;The weight ratio of the activated mixture to the glucan gel is 1:55;The glucan gel model is G-25.The molar ratio of 1,3,5-tribromobenzene to methanol is 1:95.The weight ratio of 1,3,5-tribromobenzene to the catalyst is 1:0.22,The ratio of 1,3,5-tribromobenzene to toluene is 1 g: 6.5 ml.The molar ratio of 1,3,5-tribromobenzene to triethylamine was 1:1.22.2) After cooling the system, the solid was removed by filtration, and the filtrate was added to 5 volumes of water, and then extracted with chloroform. The extract was dried over anhydrous sodium sulfate and concentrated to give a product.The molar yield was 99.5% and the GC purity was 98.9%.

References:

CN109369350,2019,A Location in patent:Paragraph 0033-0038; 0039-0044; 0045-0050

108-73-6

505 suppliers

$13.00/5g

621-23-8

517 suppliers

$7.00/5g

830-79-5

264 suppliers

$7.00/1g

621-23-8

517 suppliers

$7.00/5g