2,4-Dichlorobenzenesulfonyl chloride synthesis

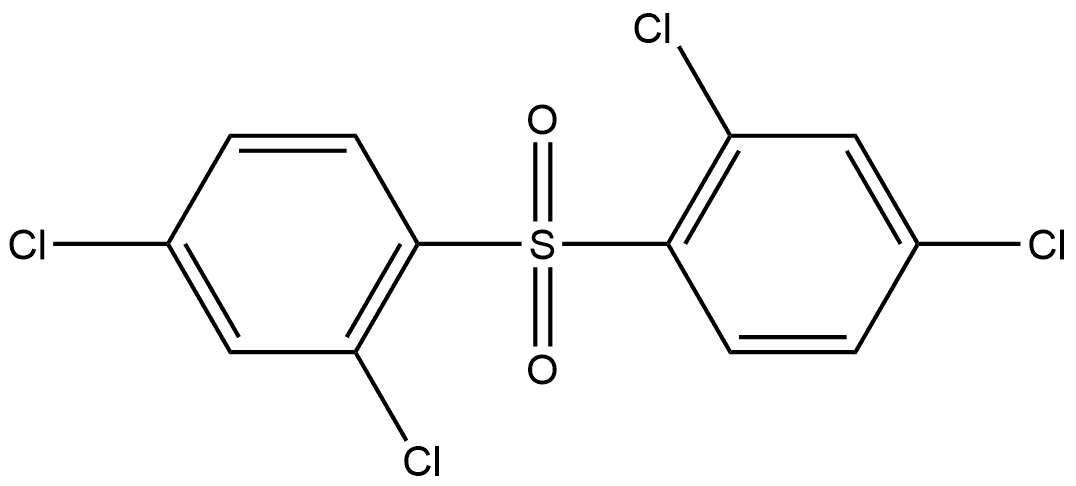

- Product Name:2,4-Dichlorobenzenesulfonyl chloride

- CAS Number:16271-33-3

- Molecular formula:C6H3Cl3O2S

- Molecular Weight:245.51

554-00-7

259 suppliers

$10.00/1g

16271-33-3

230 suppliers

$14.00/5g

Yield: 83%

Reaction Conditions:

Stage #1:2,4-Dichloroaniline with acetic acid for 0.166667 h;

Stage #2: with hydrogenchloride in water for 0.333333 h;Further stages;

Steps:

3; 6 Example 6: Theoretical experiment of a low-temperature continuous reaction device

Add acetic acid (1384g) and cuprous chloride (13g, 0.131mol, 0.1eq) into the reaction flask,Control the temperature at 20±5 and pass in the gas sulfur dioxide (93g, 1.44mol, 1.1eq), the pass is completed,Save it for later use. Add raw materials (212g, 1.31mol, 1.0eq), acetic acid (500g) to another reaction flask V-101, stir for 10min, add water (500g),Concentrated hydrochloric acid (1000g), stirred for 20min. Named as: raw material liquid.Prepare a solution of sodium nitrite (95g, 1.37mol, 1.05eq) in water (480g) in V-102,Named as sodium nitrite aqueous solution.Place the simulation device of the reactor in a dry ice bath and cool down to 0±5°C,Use peristaltic pump P-101 to beat the raw material liquid. Use plunger pump P-102 to hit sodium nitrite aqueous solution.The two raw material liquids are contacted in the reactor's simulation device, and the internal temperature of the reactor is controlled to 0±5°C.The reaction liquid overflowed from the simulation device of the reactor into the reaction bottle of sulfur dioxide acetic acid solution. The reaction solution was extracted three times with 1.4L of toluene, washed with 1.0L*3 of water, and concentrated to dryness under reduced pressure.The product was 267g with a yield of 83%.

References:

CN112538030, 2021, A Location in patent:Paragraph 0025-0028; 0038-0042

541-73-1

404 suppliers

$19.00/25G

16271-33-3

230 suppliers

$14.00/5g

609-62-1

19 suppliers

$45.00/50mg

16271-33-3

230 suppliers

$14.00/5g

7790-94-5

4 suppliers

$42.79/5 g

67-66-3

6 suppliers

$33.60/500ml

541-73-1

404 suppliers

$19.00/25G

16271-33-3

230 suppliers

$14.00/5g

7790-94-5

4 suppliers

$42.79/5 g

7664-93-9

6 suppliers

$21.64/1003

541-73-1

404 suppliers

$19.00/25G

609-62-1

19 suppliers

$45.00/50mg

6647-75-2

0 suppliers

inquiry

16271-33-3

230 suppliers

$14.00/5g