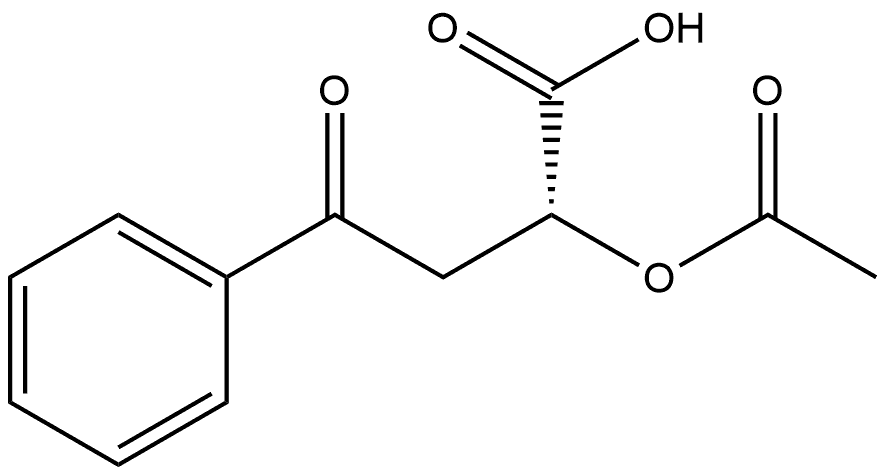

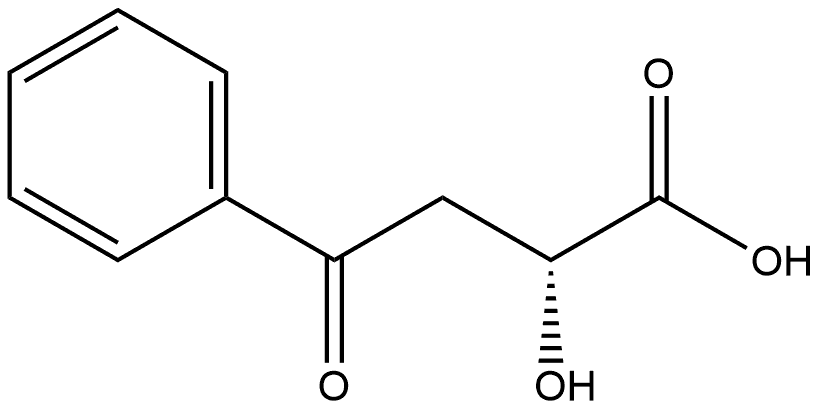

(-)-ETHYL (R)-2-HYDROXY-4-OXO-4-PHENYLBU synthesis

- Product Name:(-)-ETHYL (R)-2-HYDROXY-4-OXO-4-PHENYLBU

- CAS Number:244277-48-3

- Molecular formula:C12H14O4

- Molecular Weight:222.24

6296-54-4

86 suppliers

$21.75/1g

244277-48-3

7 suppliers

inquiry

Yield:> 99 % ee

Reaction Conditions:

with glucose dehydrogenase;D-glucose;ketoreductase;NADP in aq. phosphate buffer;water at 25 - 30; pH=6 - 6.5;Enzymatic reaction;Reagent/catalyst;

Steps:

4 Alternative 1:

To a 300 L stir tank was charged Na2CO3(6.8 kg, 0.54 w/w, 1.12 eq.) and H2O (68.0 kg, 5.4 w/w, 5.4 vol.) and stirred to dissolved at room temperature. Barreled and labeled as 9% Na2CO3 solution. To the 300 L stir tank was charged Na2CO3 (10.1 kg, 0.80 w/w, 1.66 eq.) and H2O (50.4 kg, 4.0 w/w, 4.0 vol.) and stirred to dissolve at room temperature. Barreled and labeled as 16.7% Na2CO3 solution. Washed 300 L stir tank to neutral. To the washed 300 L stir tank was charged HCl (18.0 kg, 1.43 w/w, 3.18 eq.) and H2O (15.4 kg, 1.22 w/w, 1.22 vol.) and stirred to dissolve at room temperature. Barreled and labeled as 6 M HCl solution. To a 500 L stir tank was charged A18 (12.6 kg, 1 w/w, 57.3 mol, 1.00 eq.) and ACN (2.6 kg, 0.21 w/w, 0.26 vol.) and stirred to dissolved at room temperature. To a 50 L preparation container was charged K2HPO4 (0.4 kg, 0.032 w/w, 0.04 eq.), KH2PO4 (0.6 kg, 0.048 w/w, 0.077 eq.), glucose (16.8 kg, 1.33 w/w, 1.63 eq.) and H2O (50.5 kg, 4.0 w/w, 4 vol.) and stirred to dissolved at room temperature. Barreled and labeled as glycosylated buffer solution. Transferred to 500 L stir tank at 25-30 °C (recommend: 28 °C). Washed the container with H2O (6.2 kg, 0.49 w/w, 0.49 vol.) and then transferred to the 500 L stir tank. Stirred at 25~30 °C and adjusted pH to 6.0-6.5 by titrating 9% Na2CO3. To a 50 L preparation container was charged NADP (0.069 kg, 0.0054 w/w, 0.0015 eq.), KRED 1-200-0-16 (0.284 kg, 0.023 w/w), coenzyme 1-030-0-05 (0.035 kg, 0.0028 w/w) and H2O (3.33 kg, 0.26 w/w, 0.26 vol.) and stirred to dissolved at room temperature. Then transferred to 500 L stir tank. Washed the container with H2O (5.0 kg, 0.40 w/w, 0.4 vol.) and then transferred to 300 L stir tank. Stirred at 25-30 °C (recommend: 28 °C) and maintained pH between 6.0- 6.5 (recommend: pH=6.3) by titrating 9% Na2CO3 (37.5 kg, ~2.97 vol.) for 7 h. Adjusted the pH to 1.5~2.0 (recommend: pH=1.7) by 6 M HCI solution (12.2 kg, ~0.97 vol). Stirred for 1 h. Then adjusted the pH back to 6.0~6.5 by 16.7% Na2CO3 solution (22.6 kg, 1.79 w/w, ~1.8 vol.). To a 100 L filter tank was charged celite (2.1 kg, 0.17 w/w). Filtered the reaction slurry to obtained filtrate 1 and cake 1. Transferred filtrate 1 to 500 L stir tank and cake 1 to 500 L stir tank. To 500 L stir tank was charged MTBE (93.6 kg, 7.43 w/w) and stirred for 25-35 min. (Recommend: 30 min) at 25~30 °C. Filtered the slurry to obtained filtrate 2 and cake 2. Transferred filtrate 2 to 500 L stir tank to extract filtrate 1. After phase separated, transferred the upper organic phase 1 to transit drums and the bottom aqueous phase 1 to 500 L stir tank. Transferred cake 2 to 300 L stir tank. To 500 L stir tank was charged MTBE (93.2 kg, 7.40 w/w, 10 vol.) and stirred for 25-35 min. (Recommend: 30 min). Filtered the slurry to obtained filtrate 3 and cake 3. Discard cake 3. Transferred filtrate 3 to 500 L stir tank to extract aqueous phase 1. After phase separated, transferred the upper organic phase 2 to transit drums and the bottom aqueous phase 2 to 500 L stir tank. To 500 L stir tank was charged MTBE (93.1 kg, 7.39 w/w, 10 vol.) and stirred for 25-35 min. (Recommend: 30 min). Filtered the slurry to obtained filtrate 4 and cake 4. Transferred filtrate 4 to 500 L stir tank to extract aqueous phase 2. After phase separated, transferred the upper organic phase 3 to transit drums and discarded the bottom aqueous phase 3. Combined organic phase 1, 2, and 3 and charged to 500 L stir tank. Concentrated at -0.06 MPa to -0.10 MPa and 30-40°C (optimal 40 °C) to 3- 4V (37.8-57.4L). Ethanol (~59 kg*3, ~4.7 V*3) was charged to 500 L stir tank and then concentrated to 3-4 V (37.8-50.4 L) three times to switch solvent. Obtained A7 at purity >95.0%, chiral purity >99.0% (HPLC 97 A%, Chiral HPLC > 99% ee). The obtained solution was used directly in the next step.

References:

WO2022/212809,2022,A1 Location in patent:Page/Page column 65-68

6296-54-4

86 suppliers

$21.75/1g

5650-41-9

17 suppliers

inquiry

146912-66-5

0 suppliers

inquiry

244277-48-3

7 suppliers

inquiry