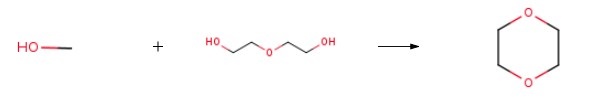

Diglyme synthesis

- Product Name:Diglyme

- CAS Number:111-96-6

- Molecular formula:C6H14O3

- Molecular Weight:134.17

Yield:-

Reaction Conditions:

with hydrogen in methanol at 200 - 350; under 750.075 - 15001.5 Torr; for 4 h;Temperature;

Steps:

3

General procedure: Cu(NO3)2 was formulated with 0.3 mol/L aqueous solution with deionized water, a solution of 157 ml of this solution was placed in a beaker, while stirring slowly add ammonia, the pH of the solution in the beaker was 9.5 to 10.5. weighed 12 g of silica was added to the above-mentioned beaker containing Cu(NO3)2 solution, in the 30 °C water bath stirring aging 4h, heated to 90 °C steamed ammonia, until the beaker solution has a pH of 7 to 8. the resulting precipitate was filtered and washed to a filtrate at a pH of about 7. the washed precipitate was dried at 120 °C for 12 h, 450 ° C calcination 4h, tablet crushing to 20 ~ 40 mesh, pre-reaction reduction to obtain catalyst A: 20 wt% Cu/silica. The above catalyst performance was evaluated in a continuous flowing gas solid phase reactor, The catalyst loading was 1.0g. using a pure hydrogen normal pressure 350 ° C reduction catalyst, flow rate of 100mL/min, the temperature is raised from room temperature to 350 ° C at a rate of 1 to 2 ° C/min, and keep 4h, down to the reaction temperature after the introduction of H2, a 15 wt.% DMO solution of methanol was poured into an advection pump. control the hydrogen ester ratio 150, The system pressure is 2.0 MPa, the reaction temperature was 200 ° C. chromatographic analysis raw materials dimethyl oxalate (DMO) and the product of methyl glycolate (MG), ethylene glycol (EG), ethanol (EO), 2-methoxyethylether (2-MEO), 1,2-propanediol (1,2POD), 1,2-butanediol (1,2BOD).The evaluation results of the catalyst performance are shown in Table 1. The catalyst preparation and evaluation procedure was the same as in Example 1, except that 12 g of silica was changed to 12 g of HZSM-5 to obtain catalyst D: 20 wt% Cu / ZSM-5. the evaluation results of the catalyst performance are shown in Table 1.

References:

CN105622418,2016,A Location in patent:Paragraph 0020; 0021; 0026; 0027

67-56-1

732 suppliers

$9.00/25ml

111-77-3

442 suppliers

$10.60/50gm:

111-46-6

1049 suppliers

$5.00/25g

123-91-1

653 suppliers

$17.00/25g

111-96-6

484 suppliers

$16.00/25mL

67-56-1

732 suppliers

$9.00/25ml

111-46-6

1049 suppliers

$5.00/25g

123-91-1

653 suppliers

$17.00/25g

111-77-3

442 suppliers

$10.60/50gm:

111-96-6

484 suppliers

$16.00/25mL

553-90-2

314 suppliers

$10.00/5g

57-55-6

1515 suppliers

$5.00/1g

96-35-5

308 suppliers

$5.00/5g

64-17-5

698 suppliers

$10.00/50g

111-96-6

484 suppliers

$16.00/25mL

107-21-1

1298 suppliers

$10.00/25g

584-03-2

163 suppliers

$8.00/5g

115-10-6

93 suppliers

$75.00/25g

110-71-4

470 suppliers

$13.00/25ml

111-96-6

484 suppliers

$16.00/25mL

20637-49-4

14 suppliers

inquiry