Dipentaerythritol synthesis

- Product Name:Dipentaerythritol

- CAS Number:126-58-9

- Molecular formula:C10H22O7

- Molecular Weight:254.28

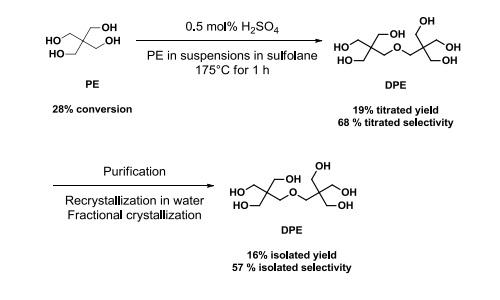

Dipentaerythritol (DPE) has been prepared from a slurry of Pentaerythritol (PE) in sulfolane catalyzed by a low amount of sulfuric acid and was isolated with 16% yield (72% GPC purity) and 57% isolated selectivity.

synthesis of dipentaerythritol from pentaerythritol under acidic conditions

115-77-5

6 suppliers

$10.00/10 g

126-58-9

300 suppliers

$5.00/10g

Yield:126-58-9 334 g

Reaction Conditions:

with 2-Ethylhexanoic acid;2-propyl heptanoic acid at 190 - 231; under 150.015 Torr; for 26.5 h;Inert atmosphere;Industrial scale;

Steps:

1 Production of mixed ester (mixed ester 1) of pentaerythritol of 79/21]

As an adsorbent, Kyowaad 500 made by Kyowa Chemical Industry Co., Ltd. was used.As the activated carbon, egret P made by Nippon Enviro Chemicals Co., Ltd. was used.82 g of pentaerythritol (0.6 mol, manufactured by K.K. Perstorp), 312 g of 2-ethylhexanoic acid (2.2 mol, manufactured by Kyowa Hakko Kagaku Kabushiki Kaisha) and 124 g of 2-propylheptanoic acid Mole, Production Example), and the mixture was degassed by bubbling nitrogen at room temperature under a reduced pressure of 20 kPa for 30 minutes while stirring the mixture.Then, the mixture was stirred at 190 to 231 ° C for 26 hours under nitrogen bubbling at atmospheric pressure. After the reaction, the reaction product was stirred under a reduced pressure of 0.9 kPa at 228 to 231 ° C for 1.5 hours to distill off the unreacted carboxylic acid in the reaction product. The reaction product was washed with 90 mL of an aqueous solution containing 200 mL of sodium hydroxide having an acid value of 2 times that of the reaction product for 1 hour at 90 ° C. Then, the reaction product was washed with 200 mL of water three times at 90 ° C for 0.5 hours. Then, the reaction product was dried while bubbling nitrogen under a reduced pressure of 0.9 kPa at 105 ° C for 1 hour.1.2 g (corresponding to 0.3% by weight of the reaction product) of the adsorbent and 4.0 g (1.0% by weight of the reaction product) of the adsorbent were added to the reaction product, and the reaction product The mixture was stirred at 106 ° C for 1 hour under a reduced pressure of 0.9 kPa and then filtered using a filter aid to obtain 334 g of mixed ester 1.

References:

KH Xinhua Co., Ltd.;An Shunye;Zhong Jingyouyilang;Tian Zhongshensi;Dao Shanjunhong CN104220415, 2016, B Location in patent:Paragraph 0102-0108

50-00-0

841 suppliers

$10.00/25g

64-18-6

1059 suppliers

$22.12/250ML

75-07-0

410 suppliers

$14.00/5mL

115-77-5

6 suppliers

$10.00/10 g

126-58-9

300 suppliers

$5.00/10g

141-53-7

709 suppliers

$6.00/100g

115-77-5

6 suppliers

$10.00/10 g

107-02-8

4 suppliers

$38.60/4s8501

126-58-9

300 suppliers

$5.00/10g

50-00-0

841 suppliers

$10.00/25g

75-07-0

410 suppliers

$14.00/5mL

115-77-5

6 suppliers

$10.00/10 g

126-58-9

300 suppliers

$5.00/10g