Glaucarubin manufacturers

- Glaucarubin

-

- $4656.00 / 1KG

-

2024-07-26

- CAS:1448-23-3

- Min. Order: 1KG

- Purity: 99.0%

- Supply Ability: 1000 tons

- Glaucarubin

-

- $4656.00 / 1KG

-

2024-07-25

- CAS:1448-23-3

- Min. Order: 1KG

- Purity: 99.0%

- Supply Ability: 1000 tons

|

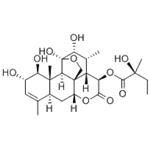

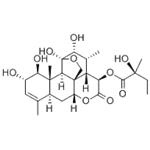

| | Glaucarubin Basic information |

| Product Name: | Glaucarubin | | Synonyms: | Glaucarubin;11β,20-Epoxy-1β,2α,11,12α-tetrahydroxy-15β-[(S)-2-hydroxy-2-methyl-1-oxobutoxy]picras-3-en-16-one | | CAS: | 1448-23-3 | | MF: | C25H36O10 | | MW: | 496.549 | | EINECS: | 815-051-1 | | Product Categories: | | | Mol File: | 1448-23-3.mol |  |

| | Glaucarubin Chemical Properties |

| Melting point | 252.5°C (rough estimate) | | Boiling point | 508.86°C (rough estimate) | | alpha | D25 +45° (c = 1.7 in pyridine); D25 +69° (c = 0.6 in methanol) | | density | 1.2066 (rough estimate) | | refractive index | 1.5376 (estimate) | | LogP | -0.436 (est) |

| | Glaucarubin Usage And Synthesis |

| Originator | Glarubin,Massengill,US,1959 | | Definition | ChEBI: Glaucarubin is a triterpenoid. | | Manufacturing Process | The preparation of pure glaucarubin from Aceituno meal is conveniently

carried out by extracting the Aceituno meal with water, using about 100

gallons of the water per hundred pounds of meal. If the meal is in the form of

a relatively solid cake, it should be soaked in the water for a time to cause

disintegration. The temperature of the water is then raised to about 70°C for

the actual extraction, and the mixture is moderately agitated, while

maintaining a temperature of about 70°C for a period of about three hours,

until extraction is substantially complete. If desired, the extraction may be

conducted at lower temperatures down to about room temperature although

at such lower temperatures, the extraction is much slower and less efficient at

temperatures substantially higher than 70°C, there may be partial destruction

or decomposition of the product being recovered.

The slurry or extraction mixture is filtered while hot, and the resulting filter

cake is washed with about five to ten gallons of hot water; the primary filtrate

and wash water are combined and held for further processing. In order to

insure complete extraction of the desired material, the filter cake is again

extracted with about 100 gallons of water at 70°C. Although not essential, it is desirable to add to the second extraction a small quantity of acetic acid.

The acetic acid appears to aid in obtaining a complete and thorough

extraction. After extraction for about three hours with agitation at a

temperature of about 70°C, the slurry is again filtered and the cake washed

as before with about five to ten gallons of hot water. The resulting filtrate and

wash are then combined with the primary filtrate and wash.

The combined filtrates or total aqueous extracts are cooled to about room

temperature and filtered to remove any residual solids from solution. The

clarified aqueous extract is then concentrated to about 70 gallons at a

temperature below about 50°C, thus reducing the volume to about one-third

the original volume. The resulting concentrate is cooled to room temperature

or below and filtered to remove any tar or gum that may have separated. The

presence of tar or gum at this stage of the process will vary depending upon

the starting material and the manner in which the primary extraction has

been carried out. It has been found, however, that unless any tar or gum

present in the initial extract is removed by the procedure described, it will

seriously interfere with the further concentration and crystallization steps

hereinafter described.

After removal of such tar or gum, the concentrate is further evaporated at a

temperature below about 50°C to about one-fourth the volume, i.e., 70

gallons is concentrated to about 15 to 20 gallons. This concentrate is cooled

to a temperature of about 0°C to 5°C and allowed to stand for an extended

period, such as overnight, whereupon there is a separation of crude crystalline

glaucarubin therefrom. The crude crystals thus formed are removed by

filtration and the mother liquors again concentrated to about one-half volume

and cooled to permit separation of a second batch of crude glaucarubin

crystals. The two batches of crude glaucarubin crystals are combined and

dried preparatory to further purification.

The crude glaucarubin crystals obtained as above described from 100 pounds

of Aceituno meal are slurried with about sevenandanehalf gallons of

anhydrous methanol and refluxed until the crystals dissolve. The hot solution

is then filtered and the resulting filter cake washed with methanol. The filter

cake is then again extracted with an additional seven-and-one-half gallon

quantity of anhydrous methanol in the manner described, and filtered. The

methanol filtrates and washes are combined and concentrated at atmospheric

pressure until crystals begin to appear, i.e., generally after concentration to

about one-fifteenth volume. The solution is then cooled to about 0°C to 50°C

and allowed to stand for crystallization to go substantially to completion. The

resulting crystals are filtered off and the mother liquors are further

concentrated and cooled to collect a second crop of crystals. The two crops of

crystals are then combined and may be further purified by redissolving in

methanol, filtering through activated charcoal, and recrystallizing after

concentration of the methanol filtrate.

The purified crystalline glaucarubin thus obtained is colorless and odorless and

is estimated to have a purity of about 96% to 97%. It has the formula

C25H36O10 and melts at 262°C to 263°C with decomposition (capillary tube). | | Therapeutic Function | Amebicidal |

| | Glaucarubin Preparation Products And Raw materials |

|