Silicon Nitride: General Properties; Industrial Preparation and Grades

Jan 16,2024

Description and General Properties

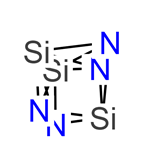

Silicon nitride, chemical formula Si3N4 and relative molecular mass of 140.284, is a medium-density ceramic material (3290 kg.m–3). The high flexural strength (830 MPa), high fracture toughness (6.1 MPa.m–1/2), and creep resistance, even at elevated temperatures, ensure a high temperature strength to silicon nitride. Moreover, its low thermal expansion coefficient (3.3 μm/m.K), combined with a Young's modulus of 310 GPa, confers upon silicon nitride a superior thermal shock resistance compared with most ceramic materials.

Application of silicon nitride

Silicon nitride has been used extensively in a number of other industrial applications, such as engine components, bearings, and cutting tools. In general, silicon nitride exhibits higher temperature capabilities than most metals, combining high mechanical strength and creep resistance with oxidation resistance. From a chemical point of view, silicon nitride exhibits an excellent corrosion resistance to numerous molten nonferrous metals such as Al, Pb, Zn, Cd, Bi, Rb, and Sn and molten salts like NaCl-KCl, NaF, and silicate glasses. However, it is corroded by molten Mg, Ti, V, Cr, Fe, and Co, and salts like cryolite, KOH, and Na2O.

Industrial Preparation

Pure silicon nitride is difficult to produce as a fully dense material because it does not readily sinter and cannot be heated above 1850°C because it decomposes into silicon and nitrogen. Dense silicon nitride can only be made using sintering aids or by the direct nitriding of silicon. Therefore, the final material properties strongly depend on the fabrication method.

Grades of silicon nitride

Three grades of silicon nitride are available commercially:

(i) Reaction bonded silicon nitride (RBSN) is a high-purity grade of silicon nitride prepared by direct nitriding of compacted silicon powder. The incomplete nitriding reaction leads to densities of only 70 to 80% of the theoretical density and usually ranges from 2300 to 2700 kg.m–3. It exhibits excellent thermal shock resistance and an outstanding corrosion resistance to molten nonferrous metals, especially aluminum metal. Reaction-bonded silicon nitride represents a cheaper alternative to the fully dense silicon nitride and can be machined to close tolerance (near-net shape) without the need for expensive diamond grinding.

(ii) Hot-pressed silicon nitride (HPSN) is obtained by applying both heat and pressure through a graphite die using sintering aids. However, most hot-pressed silicon nitride grades can be formulated with a minimum amount of densification aids. These compositions offer the highest mechanical strength of other silicon nitride grades. The major drawbacks are that only simple shaped billets can be produced by this process and the preparation of finished components requires expensive machining by utilizing diamond grinding.

(iii) Sintered silicon nitride (SSN) consists of a family of fully dense materials having a range of compositions that can be produced in cost-effective, complex net shape. The green compacts, made of powders with a high surface area, are fired under a nitrogen atmosphere, without applying pressure. This grade of silicon nitride has the best combination of properties, making it the leading technical ceramic for a number of structural applications including automotive engine parts, bearings, and ceramic armor.

(iv) Hot isostatically pressed silicon nitride (HIPSN) is obtained by glass-encapsulated parts that are placed in a high-pressure vessel or autoclave, with heat and pressure applied. The result is a slight decrease in strength but a substantial improvement in reliability. The material is used currently in niche market applications, for example, in reciprocating engine components and turbochargers, bearings, metal cutting and shaping tools, and hot metal handling.

- Related articles

- Related Qustion

Supplementation with pyridoxal 5'-phosphate monohydrate can synthesize neurotransmitters such as dopamine and serotonin, maintaining a healthy nervous system.....

Nov 4,2025Biochemical EngineeringNatural rubber has good dielectric properties, excellent resilience, an elevated damping capacity, and good tear resistance.....

Jan 16,2024Plant extractsSilicon nitride

12033-89-5You may like

- Silicon nitride

-

- $3.60 / 1kg

- 2025-06-16

- CAS:12033-89-5

- Min. Order: 1kg

- Purity: ≥99%

- Supply Ability: 3000tons/month

- Silicon nitride

-

- $0.00 / 1kg

- 2022-10-18

- CAS:12033-89-5

- Min. Order: 1kg

- Purity: 99%

- Supply Ability: 20ton/month

- Silicon nitride

-

- $0.00 / 1kg

- 2022-09-27

- CAS:12033-89-5

- Min. Order: 1kg

- Purity: 99%

- Supply Ability: 1000kg