Toxicity of Chloroprene

Jan 7,2022

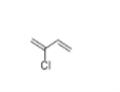

Chloroprene, 2-chloro-1,3-butadiene, is a colorless, volatile

synthetic liquid that has a pungent ether-like odor. Synthesis

of chloroprene was first reported by chemists of the E. I. du

Pont de Nemours Company in 1931 following studies of

acetylene polymerization with the objective of producing

synthetic rubber. The chloroprene monomer differs from

isoprene, the fundamental monomer of natural rubber, only

by substitution of chlorine for the methyl group of isoprene.

Chloroprene was observed to polymerize much more

quickly than did isoprene. In industrial processes prior to

1960, chloroprene was produced in relatively high yields by

reacting vinyl acetylene with hydrogen chloride. Today,

chloroprene is produced more efficiently by chlorination of

1,3-butadiene.

Characteristic

When compared with natural rubber the chloroprene synthetic polymer, polychloroprene, was noted to be much denser, more resistant to water and hydrocarbon solvents, less permeable to many gases, and was more resistant to degradation by oxygen, ozone, hydrogen chloride, hydrogen fluoride, and other chemicals. Due to desirable physical and chemical properties, polychloroprene and its latex polymers are produced in quantities exceeding 200 000 metric tons at a limited number of facilities around the world. Chloroprene production is closely tied to demand for polychloroprene.

Uses

More than 90% of chloroprene produced annually is used to make polychloroprene, which constitutes the widely known DuPont product Neoprene. This solvent-resistant elastomer, made by free radical initiated polymerization of chloroprene, is used to make many automotive rubber products, such as tires, hoses, and belts. Polychloroprene is formulated into adhesives and latex emulsions for dip coated goods. Other products made from polychloroprene are rubber personal protection garments including gloves, shoes, and wetsuits. Polychloroprene is used in conveyor and transmission belts, sealing materials, and electrical insulating materials.

Environmental Fate

Chloroprene is not known to occur naturally. It is not widely distributed in the environment due its reactivity and its use at a limited number of facilitiesworldwide. Industrial productionof chloroprene is accomplished in sealed reactor systems with very limited fugitiveemissions.Polymerizationprocesses are designed to be sealed, but must be opened to remove and manipulate formed polymer. Such opening causes most environmental release of chloroprene, the majority of which enters the atmosphere. From National Library of Medicine Toxics Release Inventory 2010 data, more than 270 000 pounds of chloroprene was released into the environment. Of that amount more than 97% was released into air at one site in Louisiana, USA.

Mechanism of toxicity

The mechanisms of chloroprene toxicity differ depending on the extent and duration of exposure. An acute exposure to large concentration causes central nervous system depression typical of exposure to hydrocarbons. Organ and cellular toxicities due to reactions of chloroprene or metabolites with cellular constituents are evident. Detailed mechanisms of acute toxicities such as formation of edema and hemorrhage in tissues following large exposures are not yet known. Chronic toxicity is related to the mutagenic potential of oxidative metabolites of chloroprene, as these react with specific nucleoside sites in DNA.

- Related articles

- Related Qustion

- Chloroprene: Properties, Production process and Uses Mar 22, 2024

Chloroprene is mainly used for production of neoprene by free radical emulsion polymerization. The polymerization of chloroprene is initiated using potassium persulfate.

Trichloroacetate, or trichloroacetic acid, is a strong acid prepared by the reaction of chlorine with acetic acid in the presence of a suitable catalyst.....

Jan 6,2022Organic SolventsChloroquine (CQ) and hydroxychloroquine (HCQ) are synthetic 4-aminoquinolines. CQ has been used as an antimalarial drug since World War II. Later, CQ’s use expanded to include management of systemic lupus erythematosus (SLE) and rheumatoid....

Jan 7,2022API2-chloro-1,3-butadiene

126-99-8You may like

2-chloro-1,3-butadiene manufacturers

- Chloroprene

-

- $6.60 / 1KG

- 2019-12-24

- CAS:126-99-8

- Min. Order: 500g

- Purity: 98%

- Supply Ability: 50g, 1kg, 50kg,100kg