UV absorber-928 synthesis

- Product Name:UV absorber-928

- CAS Number:73936-91-1

- Molecular formula:C29H35N3O

- Molecular Weight:441.61

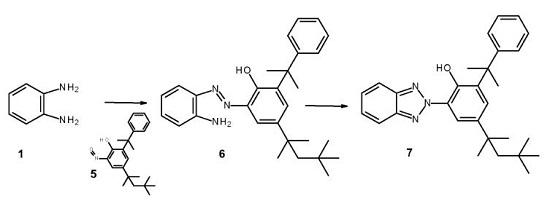

In a dry argon atmosphere 0.150 g of oxime 5, 0.070 g of 1,2-phenylene diamine 1 and 0.150 ml triethyl-borate are dissolved in 4 ml dry THF and heated for 24 h at 60°C. After a TLC shows consumption of starting oxime the mixture is evaporated to dryness and the resulting residue purified by column chromatography (eluent: hexane - ethyl acetate: 10-1 vol/vol) to give 0.171 g (92 %) of the diazo-amine intermediate 6. Replacing the B(OEt)3 by 2.5 g of basic AI2O3 and the THF by 2 ml of xylene and heating this mixture to 140°C for 48 h gives after the usual work-up 0.089 mg of diazo compound 6 and 0.300 g of starting oxime 5. According the procedure given for the preparation of compound 4 in example 1, triazole 7 is obtained from 0.007 g (0.016 mmol) of intermediate amine 6 and 0.020 g (0.122 mmol) CuSO4 in 100% (0.007 g). In this comparative example, 7.73 equivalents of copper salt are used.

3147-75-9

387 suppliers

$15.00/5g

98-83-9

293 suppliers

$10.00/25mL

73936-91-1

134 suppliers

$34.00/5G

Yield:73936-91-1 90.3%

Reaction Conditions:

with methanesulfonic acid at 175 - 180; for 6.5 h;Inert atmosphere;Temperature;

Steps:

1.1; 1.2; 2.1; 2.2; 3.1; 3.2 Example 3

A method for preparing a UV absorber Tinuvin 928, the process steps are as follows:

(1) Product synthesis:With a stirrer, thermometer, return tube,2-[2-hydroxy-5-tert-octylphenyl)benzotriazole (UV-329) 32.34g was charged into the reactor of the metering pump.Methanesulfonic acid 12.94g,And pass nitrogen protection, under slow and constant stirring conditions,The reaction mixture was heated to 175 ° C,And at a temperature of 175 ° C ~ 180 ° C with a metering pump 19.40g of α-methylstyrene was added to the liquid level below the reaction solution at a constant rate, about 6h drip,The reaction was then incubated at 180 ° C for 0.5 h.

(2) Product purification:After the reaction is completed, the reaction mass is cooled to 95 ° C to 100 ° C.The layers were allowed to stand, the lower layer was methanesulfonic acid and unreacted UV-329, and the upper layer was a crude product.The crude product was washed twice with 100 mL of 4% aqueous sodium bicarbonate solution, then twice with 100 mL of deionized water, and then the crude product was dissolved in 80 g of toluene.Decolorization treatment was carried out with 10 g of activated clay.The decolored solution is cooled and crystallized and filtered.And dried at 90 ° C ~ 100 ° C to obtain 39.83g light yellow product (theoretical amount 44.1g),The yield is 90.3%, the purity is 99.29%,The melting point is from 107 ° C to 110 ° C (literature value of 108 ° C to 110 ° C).The product of this example was identified according to the characterization method in Example 1, and it was confirmed that the product obtained in this example was the target product Tinuvin 928.

References:

CN110003126,2019,A Location in patent:Paragraph 0031-0048

73936-80-8

19 suppliers

inquiry

73936-91-1

134 suppliers

$34.00/5G